Beginning with How Altium Auto Route Transforms Modern PCB Design, the narrative unfolds in a compelling and distinctive manner, drawing readers into a story that promises to be both engaging and uniquely memorable.

Altium Auto Route plays a crucial role in modern PCB design, revolutionizing the way circuits are created and optimized. This article delves into the key features, benefits, and best practices of using this automated routing tool to enhance efficiency and accuracy in PCB design.

Introduction to Altium Auto Route

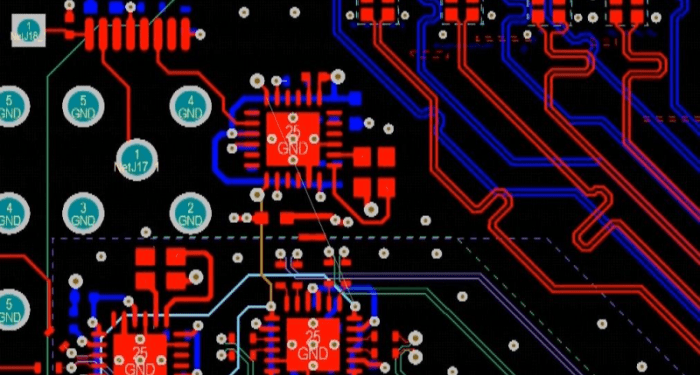

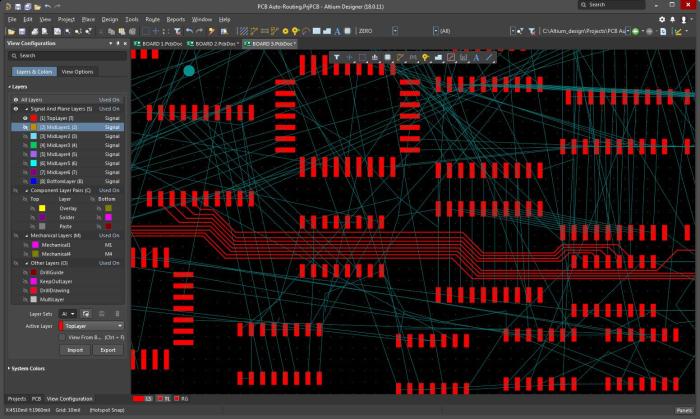

Altium Auto Route is a cutting-edge feature in PCB design software that automates the process of routing connections between components on a printed circuit board. This tool plays a crucial role in streamlining the design process and improving efficiency.

Significance of Automated Routing in Modern PCB Design

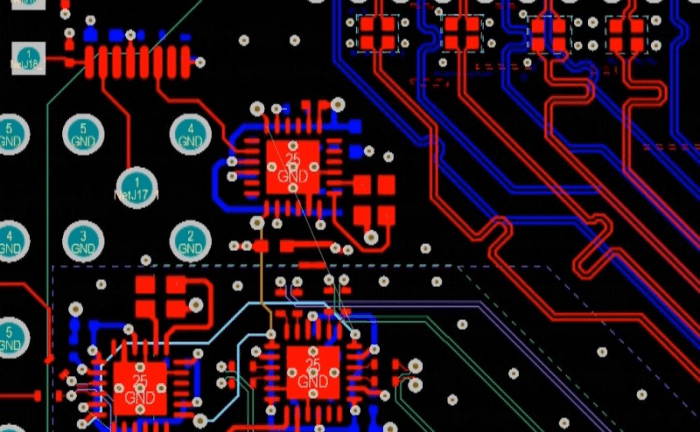

Automated routing, such as Altium Auto Route, is essential in modern PCB design due to the complex and intricate nature of circuit layouts. Manual routing can be time-consuming and prone to errors, especially in designs with high component density.

- Automated routing tools like Altium Auto Route help optimize the layout of traces to ensure signal integrity and reduce electromagnetic interference.

- By automating the routing process, designers can save significant time and effort, allowing them to focus on other aspects of the design.

- Altium Auto Route also helps in achieving a more efficient use of board space, resulting in smaller and more compact PCB designs.

Challenges in Manual Routing Overcome by Altium Auto Route

Manual routing poses several challenges that Altium Auto Route effectively addresses:

- Difficulty in routing dense designs with numerous components, which can lead to signal integrity issues.

- Risk of human error in manually routing traces, potentially causing connectivity problems or design flaws.

- Time-consuming nature of manual routing, especially in designs with complex signal paths, hindering overall design productivity.

Key Features of Altium Auto Route

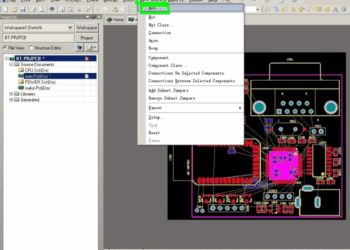

Altium Auto Route offers several key features and capabilities that significantly enhance the PCB design process, improving efficiency and accuracy in routing.

Interactive Routing

Altium Auto Route provides interactive routing tools that allow designers to easily route traces between components by dragging the mouse, automatically creating connections while maintaining design rules.

Real-Time Feedback

Designers receive real-time feedback on signal integrity, impedance control, and other important design considerations, enabling them to make informed decisions and adjustments as needed during the routing process.

Automated Net Selection

Altium Auto Route automatically selects the appropriate nets for routing based on the design requirements, reducing the manual effort required to assign connections and ensuring a more efficient routing process.

Collision Detection

The software includes collision detection capabilities that alert designers to potential conflicts or errors in the routing, helping to prevent costly mistakes and ensuring a reliable final design.

Customizable Design Rules

Altium Auto Route allows designers to set and customize design rules for routing, ensuring that the final PCB layout meets specific requirements and standards while streamlining the design process.

Comparison with Manual Routing

When comparing Altium Auto Route with traditional manual routing methods, it is essential to understand the advantages and disadvantages of each approach to determine the most suitable option for a specific PCB design project.

Advantages of Automated Routing Tools

- Efficiency: Automated routing tools like Altium Auto Route can significantly reduce the time required for routing complex PCB layouts.

- Consistency: Automated tools ensure consistent routing quality throughout the design, minimizing errors and improving reliability.

- Optimization: Auto Route can optimize routing paths based on design constraints and requirements, leading to better signal integrity and performance.

- Complexity Handling: Automated tools excel at handling high-density PCB designs with intricate routing requirements that may be challenging for manual routing.

Disadvantages of Automated Routing Tools

- Limited Creativity: Automated tools may lack the creative intuition and problem-solving skills that human designers bring to manual routing.

- Less Control: Designers have less control over the routing process when using automated tools, potentially leading to suboptimal results in certain cases.

- Learning Curve: Mastery of automated routing tools like Altium Auto Route requires training and experience, which can be a barrier for some designers.

- Cost: Implementing automated routing tools may involve additional costs for software licenses and training compared to manual routing methods.

When to Prefer Manual Routing

While automated routing tools offer numerous benefits, there are situations where manual routing may be preferable:

- High-Speed Signals: Manual routing allows designers to fine-tune high-speed signal paths for optimal performance and signal integrity.

- Specific Design Requirements: For unique or specialized design requirements that automated tools may not address effectively, manual routing can offer more flexibility.

- Artistic Considerations: In cases where aesthetics or creative layout considerations are crucial, manual routing enables designers to showcase their artistic skills.

- Small-Scale Projects: For simple or small-scale PCB designs, manual routing can be more straightforward and efficient without the need for complex automation.

Best Practices for Utilizing Altium Auto Route

When utilizing Altium Auto Route for PCB design, it is important to follow best practices to optimize its use effectively. Setting up design rules and constraints correctly and being aware of common pitfalls can greatly improve the efficiency and accuracy of the automated routing process.

Optimizing Design Rules and Constraints

- Define clear design rules: Establish specific rules for trace width, spacing, and other parameters to ensure consistency throughout the PCB layout.

- Use design constraints: Set up constraints such as signal integrity requirements, differential pair routing, and length matching to guide the auto routing process accurately.

- Consider layer stackup: Take into account the layer stackup configuration and signal layers to optimize signal integrity and impedance control.

Avoiding Common Pitfalls

- Over-reliance on automation: While Altium Auto Route can streamline the routing process, it is essential to manually review and adjust critical traces for optimal performance.

- Ignoring design rule violations: Regularly check for design rule violations and address them promptly to prevent routing errors and signal integrity issues.

- Not considering component placement: Proper component placement plays a significant role in routing efficiency, so plan component locations strategically before initiating auto routing.

Closing Notes

In conclusion, Altium Auto Route offers a transformative approach to modern PCB design, simplifying complex routing tasks and improving overall design quality. By leveraging the capabilities of this tool effectively, designers can achieve faster turnaround times and more reliable circuit layouts.

Helpful Answers

What is Altium Auto Route and how does it impact modern PCB design?

Altium Auto Route is an automated routing tool that significantly enhances the efficiency and accuracy of PCB design by streamlining the routing process and overcoming challenges associated with manual routing methods.

What are the key features of Altium Auto Route?

Some key features include intelligent routing algorithms, design rule checking, and constraint management that streamline the design process and ensure optimal routing outcomes.

When is it preferable to use manual routing over automated routing?

Manual routing may be preferred in situations where specific design requirements or constraints cannot be effectively handled by automated tools, or when a designer seeks more control over the routing process.